ABOUT US

To provide you with professional

Special equipment design and manufacturing services

Hebei Guangrun Heavy Industry Machinery Co., Ltd.Have Special equipment A2 pressure vessel manufacturing, installation, modification and maintenance license issued by the General Administration of Quality Supervision, Inspection and Quarantine. Annual production capacity of 18000 tons/year. And has passed the IS09001 international quality system certification, China Chemical Equipment Association member units.

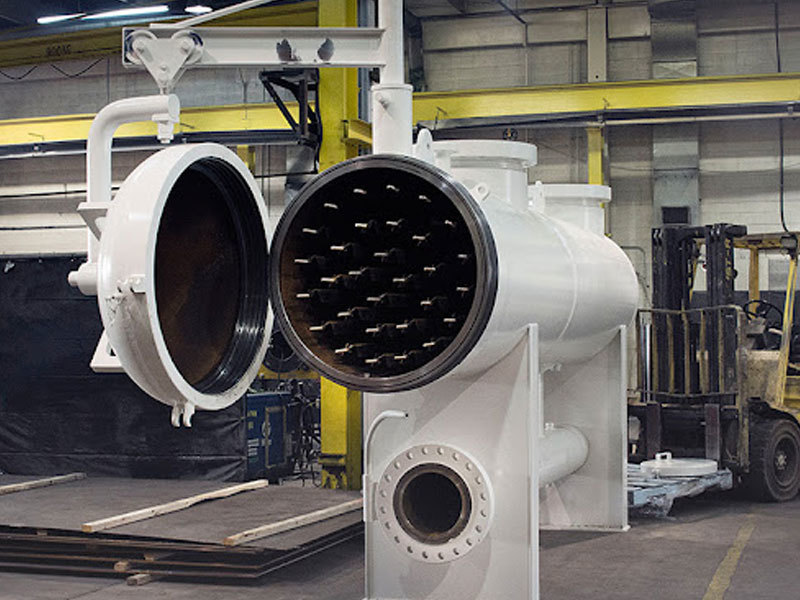

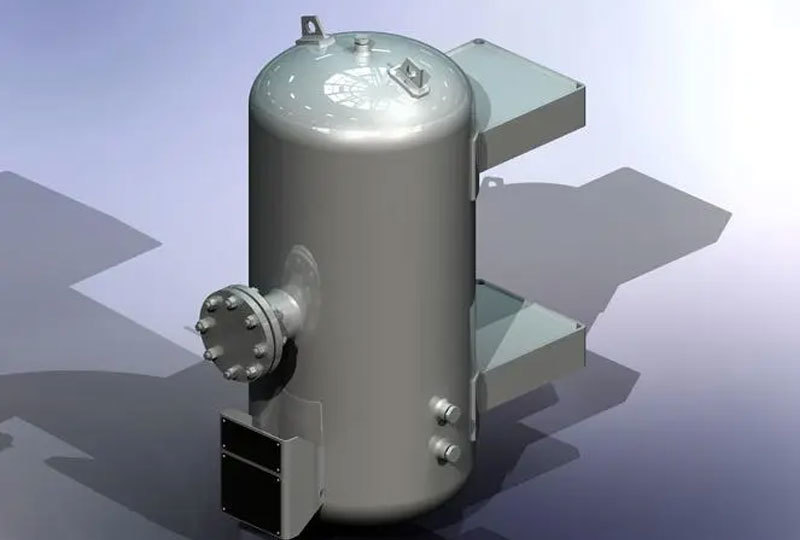

The main products are complete sets of static equipment required by the chemical, chemical fertilizer, oil refining, gas, food, and pharmaceutical industries; various carbon steel, stainless steel containers, stainless steel composite plate containers, titanium composite plates, titanium alloy composite plate containers, reactors, heat exchangers, Separators, towers, storage tanks, etc.. Over the years, the company has contracted the production of pressure vessels and pipe fittings for many large-scale projects at home and abroad, and has rich production experience and practical ability. The products are exported to the United States, Southeast Asia, the Middle East and other countries, and are well received by users.

Established in 2015

Total assets of the company

Covers an area

Annual production capacity

Many customers recognized

PRODUCTS

To provide customers with quality products

APPLICATION

Provide one-stop solution

BLOG

Real-time insight into industry needs

Looking forward to cooperating with you

The main products are chemical, chemical fertilizer, oil refining, gas, food, pharmaceutical industry required complete sets of static equipment; all kinds of carbon steel, stainless steel container, stainless steel composite plate container, titanium composite plate, titanium alloy composite plate container, reactor, heat exchanger, separator, tower, storage tank, etc. Over the years, the company has contracted the production of pressure vessels and pipe fittings for many large-scale projects at home and abroad, and has rich production experience and practical ability. The products are exported to the United States, Southeast Asia, the Middle East and other countries, and are well received by users.